viva_brasil

Well-known member

Before:

After:

I have a 2VSBK build, which is off waiting in the corner while I work on this new endeavor... Started as a 999S I bought from a forum member with the intention of using it as a donor for parts. But I really like the engine. So my plan is to continue working on the 2VSBK concept, with 4 valve and 2 valve variants. 4VSBK may be redundant... but what I mean by SBK is super light and awesome.

The bike is currently on the jig / stand, here's the list of to-do's:

- Get rid of the airbox / pod filter design

- New fuel lines... might as well

- Custom exhaust

- Custom subframe

- Figure something out for the front end... small and functional

- Maybe 848 / 1098 front end, have some stuff lying around

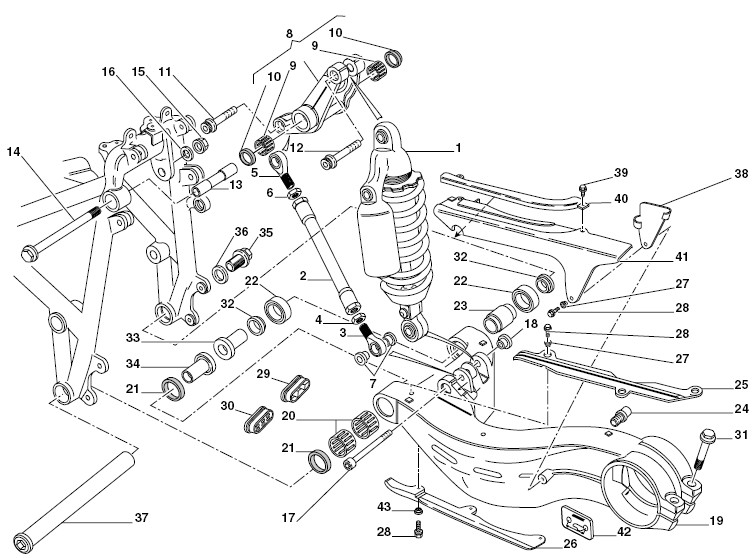

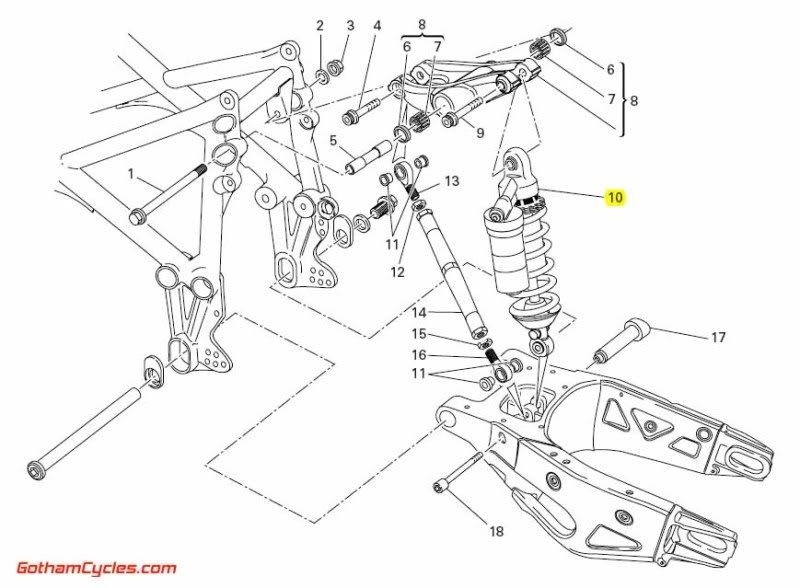

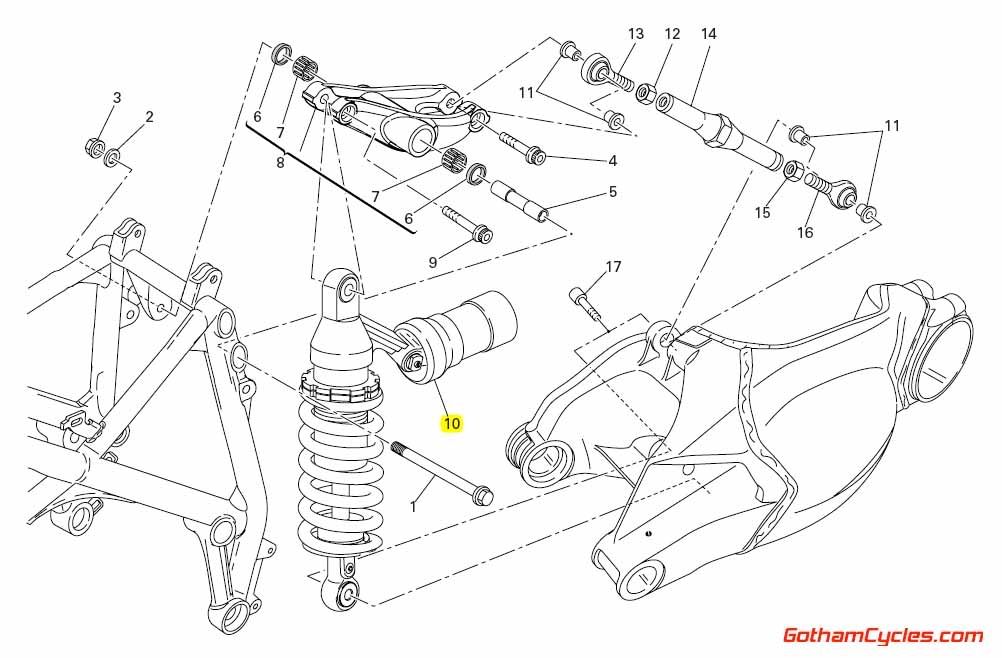

- See if I can use this friggin awesome K-Tech rear shock

Stuff I've already done: I made a jig / stand for these bikes (fits most Ducati motors at least through the 999 model range) to make sure everything is nice and straight. And I got started with the airbox / pod filter design. Some pics to kick things off...

Motorcycle stand thing in the making

The plates on the engine that will connect to the base:

The base that slots into the jig:

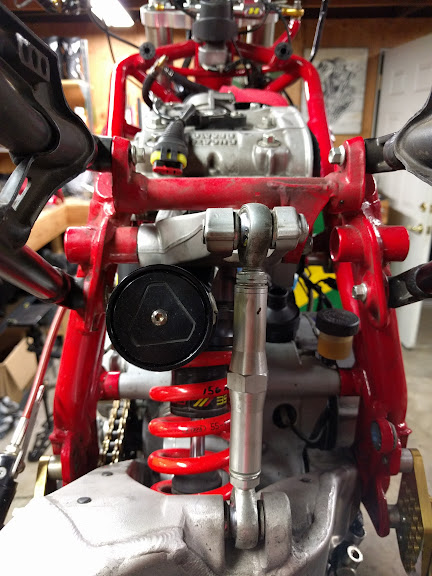

All welded up and holding the engine. Note for "levelness" I first ensured the jig was perfectly level. Then when lining up the engine / frame - I ensured the frame was perfectly level and tacked it up as such:

A shot of the frame:

Aaand finally with the 999S mounted, note I had done a good amount of stripping before putting it up - removed exhaust, removed the tank and seat as well as airbox and throttle bodies:

Split that nasty headlight open, pulling out the projectors...

The throttle body design is very interesting on these... definitely a challenge to get rid of the airbox. No pod filters available, so decided to make my own.

Some tracing....

Plasma cutting circles!

ooohhh yes

The "pod" part of pod filter... or "cone". I used the wood as a jig to drill the holes and hold the rod. Not a big deal for little low-amp welds on thin stuff:

And almost finished cone structure, just need to trim the rods sticking out the bottom and drill the bolt holes to bolt it to the base plate:

After:

I have a 2VSBK build, which is off waiting in the corner while I work on this new endeavor... Started as a 999S I bought from a forum member with the intention of using it as a donor for parts. But I really like the engine. So my plan is to continue working on the 2VSBK concept, with 4 valve and 2 valve variants. 4VSBK may be redundant... but what I mean by SBK is super light and awesome.

The bike is currently on the jig / stand, here's the list of to-do's:

- Get rid of the airbox / pod filter design

- New fuel lines... might as well

- Custom exhaust

- Custom subframe

- Figure something out for the front end... small and functional

- Maybe 848 / 1098 front end, have some stuff lying around

- See if I can use this friggin awesome K-Tech rear shock

Stuff I've already done: I made a jig / stand for these bikes (fits most Ducati motors at least through the 999 model range) to make sure everything is nice and straight. And I got started with the airbox / pod filter design. Some pics to kick things off...

Motorcycle stand thing in the making

The plates on the engine that will connect to the base:

The base that slots into the jig:

All welded up and holding the engine. Note for "levelness" I first ensured the jig was perfectly level. Then when lining up the engine / frame - I ensured the frame was perfectly level and tacked it up as such:

A shot of the frame:

Aaand finally with the 999S mounted, note I had done a good amount of stripping before putting it up - removed exhaust, removed the tank and seat as well as airbox and throttle bodies:

Split that nasty headlight open, pulling out the projectors...

The throttle body design is very interesting on these... definitely a challenge to get rid of the airbox. No pod filters available, so decided to make my own.

Some tracing....

Plasma cutting circles!

ooohhh yes

The "pod" part of pod filter... or "cone". I used the wood as a jig to drill the holes and hold the rod. Not a big deal for little low-amp welds on thin stuff:

And almost finished cone structure, just need to trim the rods sticking out the bottom and drill the bolt holes to bolt it to the base plate:

Last edited: