ToxicMark

The dose makes the poison

Hey all,

I'm working on a supermoto build using a 2011 yz250f and am close to finished. Catch cans are the last thing I am working on. Crank case breather hose catch can - check. Carb catch can - check. Coolant catch can - check...but what does it matter because coolant is leaking out of my bike from somewhere where a catch can can't go.

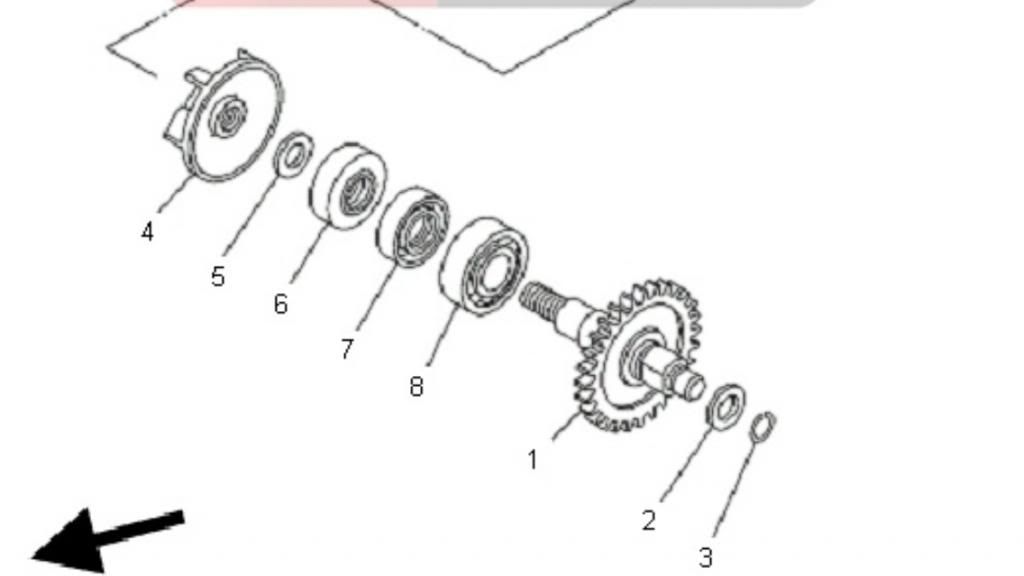

Just below and under my water pump cover and right above the oil line is a hole where coolant is dripping out from when the bike is running. Is it supposed to do that? Is there supposed to be a bolt in that hole? I know the hole is hard to see from the pictures, but it's there.

Thanks for any help in advance.

I'm working on a supermoto build using a 2011 yz250f and am close to finished. Catch cans are the last thing I am working on. Crank case breather hose catch can - check. Carb catch can - check. Coolant catch can - check...but what does it matter because coolant is leaking out of my bike from somewhere where a catch can can't go.

Just below and under my water pump cover and right above the oil line is a hole where coolant is dripping out from when the bike is running. Is it supposed to do that? Is there supposed to be a bolt in that hole? I know the hole is hard to see from the pictures, but it's there.

Thanks for any help in advance.